Halogen-free Flame Retardant Scheme for Automotive Nylon

Release time:

2023-11-13 18:05

Source:

According to relevant statistics, 14.3 percent of the world's greenhouse gases come from the automotive industry. In recent years, energy conservation and environmental protection have become a revolutionary issue in the low-carbon development of the automotive industry. The use of automotive materials also revolves around these two major topics and is developing in the direction of lightweight. The use of lightweight and higher performance alternative materials and new molding processes has become the mainstream of automotive development.

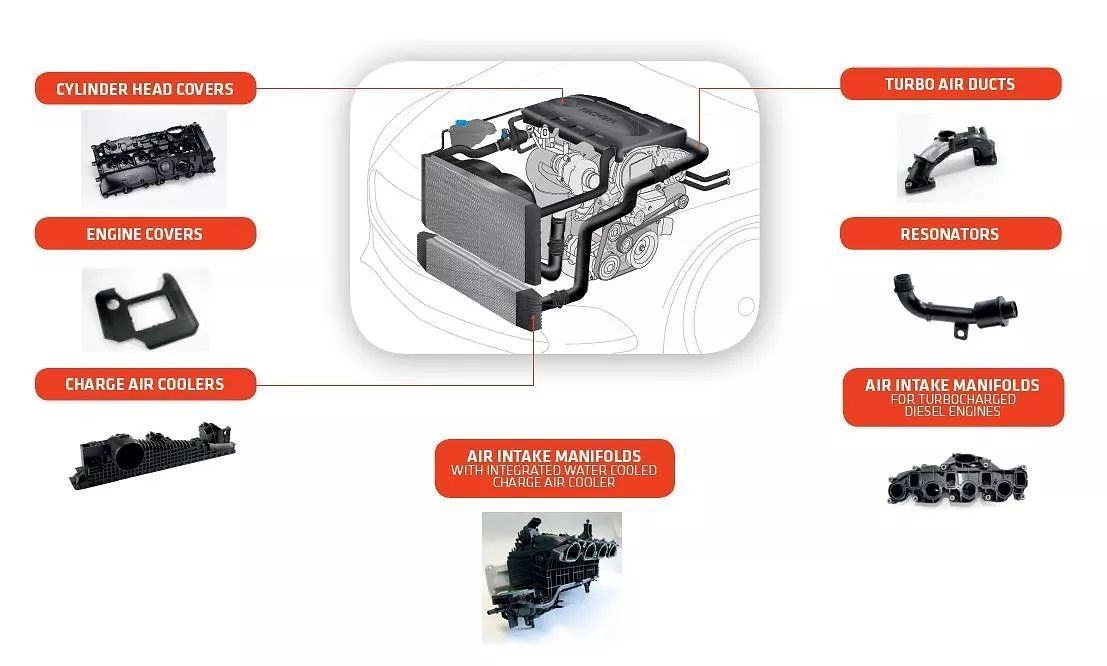

L the weight of the car is reduced by 1%, which can save 1% of fuel. The moving parts of the car are reduced by 1%, which can save 2% of fuel. Therefore, lightweight has become the main direction of the development of automotive materials. In the automobile industry, a large number of plastic instead of steel can not only meet the requirements of comprehensive performance of automobile design, that is, lightweight, safety, anti-corrosion, modeling and comfort, but also help reduce costs and save material resources. Nylon is an engineering plastic with good comprehensive performance and is gradually becoming a lightweight material for automobiles.

| Around the car engine | Average weight of components (kg) | Number of vehicles using PA6 and 66 (10,000) | Total number of vehicles (million) |

Percentage of PA used | PA6 percentage used | PA66 percentage used | Use of other raw materials |

| Engine trim cover | 0.9 | 176 | 221 | 78% | 60% | 18% | PP |

| cylinder cover | 2.0 | 122 | 174 | 70% | 8% | 62% | Metal or alloy |

| Timing belt cover | 1.5 | 23 | 125 | 18% | 15% | 3% | Metal alloy or PP |

The advantages of the application of nylon in the inner compartment of automobile engines are: excellent mechanical toughness, high temperature resistance, and aging resistance.

In recent years, with the rapid development and popularization of new energy vehicles all over the world, nylon materials have also occupied a place in the material selection of automobile charging piles. Although different countries have different standard requirements for charging piles, nylon can still adapt to the requirements of various regions by changing its performance.

| Three global mainstream charging pile standards | |

| China National Standard | GB/T 20234.2 |

| International Electrotechnical Commission Standards | IEC 62196 |

| American Society of Automotive Engineers Standard | SAE J1772 |

Material requirements for high-voltage connectors and charging systems of new energy vehicles

Pure electric vehicles and plug-in hybrid vehicles generally adopt high voltages of more than 300V and high currents of several hundred amperes. The high-voltage circuit is a key component of the vehicle's high-voltage electrical system. Its reliability and safety are related to the reliability of the vehicle system and even personal Safety, etc., are the guarantee for the safe operation of new energy vehicles. It involves the motor, electronic control, battery, and high-voltage connector as an important part of the connection of each functional module of the vehicle and the high-voltage circuit, and its accurate design analysis and selection are of great significance to electric vehicles. Select the material according to the different environmental requirements of the parts. Basic requirements for materials,

1. Flame retardant UL94 V0@0.4mm/0.8mm and excellent electrical insulation CTI 600V,GWIT>750 ℃,GWFI>850 ℃;

2. Adapt to a variety of color solutions and good color stability;

3. Long-term use temperature RTI130 ℃;

4. Excellent mechanical properties and dimensional stability.

Halogen flame retardant burning release a lot of smoke, toxic, causing great harm and pollution to the human body and space. The comprehensive characteristics of organic phosphorus flame retardant, such as high temperature resistance, processing performance, color adaptability, non-toxic, environmental protection and easy recovery, provide excellent performance for nylon flame retardant modification.

l The various parts of the car also have different requirements for materials, such as heat resistance, abrasion resistance, corrosion resistance, etc. Nylon is a very suitable material for modification, and the high performance of nylon can be realized through modification.

Nylon is a self-extinguishing polymer with an oxygen index (LOI) of 24%, which has certain flame retardant properties. Non-modified nylon reached UL94V2 level GWIT up to 650 ℃, but in the combustion process to produce dripping. Can not meet the stringent application requirements, such as electronics, electrical appliances, thin-walled, halogen-free and efficient flame retardant requirements.

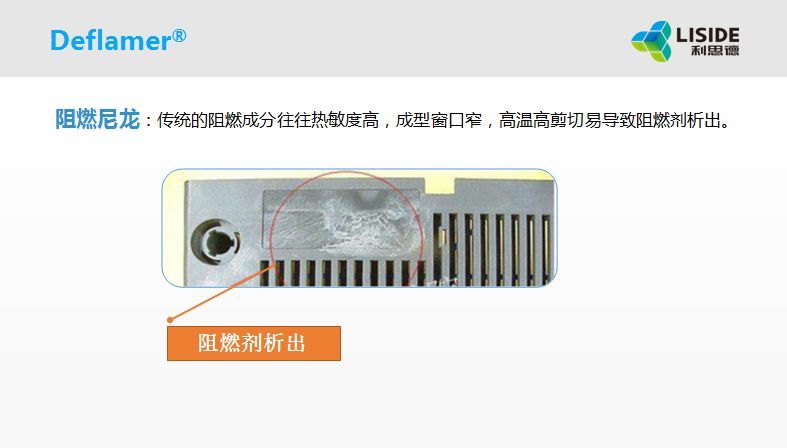

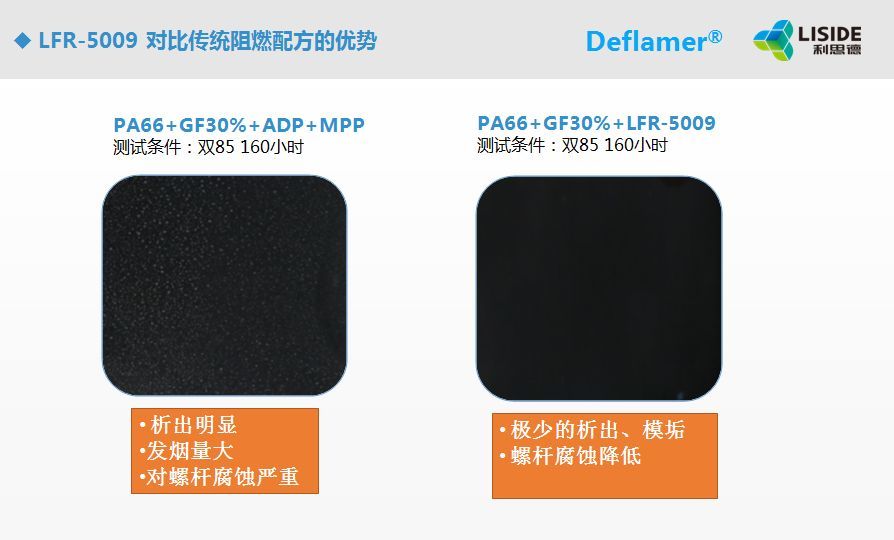

Flame retardant nylon is much more demanding than ordinary nylon process. Traditional flame retardant ingredients are often high heat sensitivity, narrow molding window, high temperature high shear easily lead to flame retardant precipitation, material flower, mechanical properties decline, discoloration and other issues.

L LEAside DeflamerR Flame Retardant Solution

L what can leiside DeflamerR flame retardant bring you?

We use optional cookies, improve your experience on our website through social media connections and other means, and advertise personalized ads based on your online activities. If you refuse the optional cookies, we will only use the cookies necessary to provide you with the service. Privacy Statement

Mobile website

Alibaba

Jiangsu Liside New Material Co., Ltd

Tel: +86-523-88960000

E-mail: liside@liside.com

Add: No. 88 Zhonghua East Road, Tianmushan Street, Jiangyan District, Taizhou City, Jiangsu Province

MD: No. 13 Zhengtai Qiling Garden, Luotang Street, Jiangyan District, Taizhou City, Jiangsu Province

Copyright: Jiangsu Liside New Material Co., Ltd

SAF Coolest v1.3.1.2 设置面板 HTESX-ZTUS-OESDE-ZFX

无数据提示

Sorry, the current column is being updated, please stay tuned!